Case Studies

Enhanced Oil Recovery

A major oil and gas company in North America implemented an Enhanced Oil Recovery (EOR) process in a mature field with medium-heavy oil. The EOR technologies utilized were polymer flooding and Alkaline Surfactant Polymer (ASP) flooding. While this increased production rates significantly, it resulted in highly emulsified produced water with higher concentrations of oil from the free water knockout outlet.

Heavy Oil Production

A major oil company with operations in southeastern Europe was generating 15,000 bpd of produced water from its heavy oil production facility. The API of the oil was 5 – 9 and the produced water was approximately 60°C with appreciable concentrations of diluents that emulsified the oil. The oil had very high concentrations of asphaltenes and Diesel Range Organics (DRO) with solid concentrations fluctuating from 50 to 800 ppm.

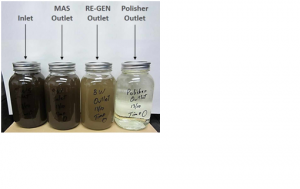

Offshore Produced Water Treatment

A super major oil and gas company operating in the Gulf of Mexico on a deepwater FPF hub servicing wells at depths of 7,000 feet needed a tertiary treatment solution to intermittently support the primary and secondary treatment equipment. The hub experienced process upsets due to the addition of production chemicals (LDHI and hydrate inhibitor), well and platform shut-ins, new wells on line, compliance checking, well testing and production rate adjustments. Their existing tertiary treatment system was large and cumbersome, requiring large lift plans for monthly servicing, and two dedicated operators to be housed on board.

Oil and WSO Removal

A major oil company producing 35k bpd and 160 MMCF/D experienced slight overages in discharges averages for compliance under the NPDES monthly discharge averages. The deepwater production region was beginning to show higher water cut and concentration of WSO compounds.

Onshore Produced Water Treatment

Anadarko is generating 10,000 barrels per day of produced water on four sites in Vernal, Utah. The produced water has light fuel condensate that has the tendency to form strong emulsions as well as high concentrations of iron sulphides that pose a unique challenge in treating the produced water.

Sheen-free Ponds for Hydraulic Fracturing

This case study will cover three hydraulic fracturing sites requiring a fail-safe solution for no oil sheen and lower production costs through site specific sustainable water treatment approaches that allowed producers to recycle and reuse produced water and/or flowback. According to New Mexico Rule 34 oil sheen compliance requirement, 19.15.34.13 Operational Requirements for Recycling Containments, states that “the operator shall maintain and operate a recycling containment in accordance with the following requirements: The operator shall remove any visible layer of oil from the surface of the recycling containment.”

Storage and Terminal Facility Wastewater Treatment

Adaptable, on-site automated water treatment solution for condensate, stormwater and wastewater in order to discharge into the Houston Ship Channel in accordance with the EPA’s National Pollutant Discharge Elimination System (NPDES) permitting program and Coast Guard Authority requirements.

Comment(1)

comment free proxy says

May 8, 2019 at 10:15 pmHi there,I log on to your new stuff named “Produced Water Case studies |” on a regular basis.Your story-telling style is awesome, keep it up! And you can look our website about free proxy.